Choose Your Robust Machines, Now!

- Decades of Expertise

- Fast Delivery

- Self-Sufficiency

- Extended Warranty

- Advanced Technology

- Precision CNC Machining

- Automated Operations

- Expert Craftsmanship

- Customization Capability

- High-Quality Material

- Durable Rollers

- Tailored Solutions

- Reliable Quality

- Low Maintenance

- Purchase Guarantee

- Ongoing Support

- On-Site Setup and Training

- Quick Troubleshooting

Experience Vorlinn's Difference in Every Side

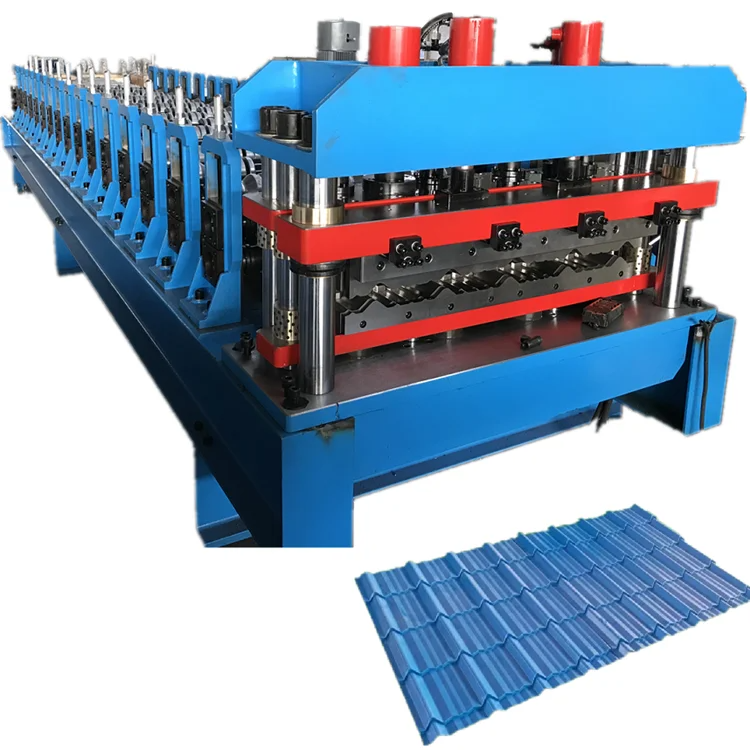

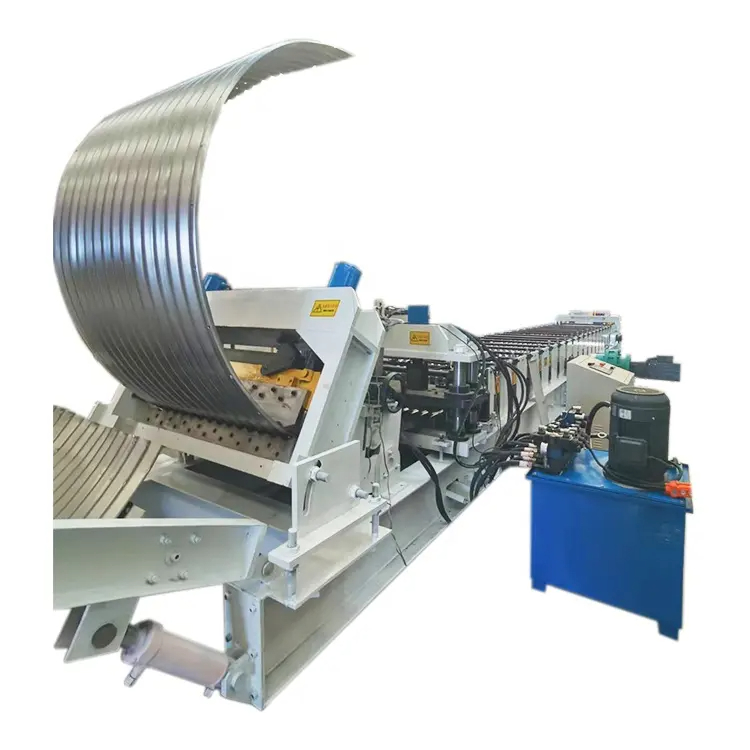

Engineered for Higher Efficiency, Fewer Malfunctions, Lower Maintenance, and Sustained Performance.

Welcome to Vorlinn!

At Vorlinn, we understand that your business requires more than just machinery— it needs innovative solutions that contribute to your success. With 17 years of experience, we are capable of crafting high-precision metal forming machines tailored to streamline your operations and enhance efficiency.

We have established successful partnerships with companies across more than 50 countries, delivering solutions that not only meet but exceed their manufacturing demands. We support our products with a 2-year warranty and offer lifetime service, ensuring your long-term success.

Are you ready to achieve your production goals? Let’s connect to discuss how we can support your needs.

How Can We Do?

Machine Design and Construction

Our R&D team, staffed with senior engineers who have over decades of experience, understands the nuances of metal forces and strains during the forming process and focuses on developing machines that are robust and reliable.

Equipped with advanced tools like CNC lathes, grinders, and heavy-duty gantry planers, our machining center ensures that each machine we produce meets the highest standards of quality and precision.

Behind Every Machine, There’s a Story of Dedication and Precision

Step into the heart of VORLINN with exclusive behind-the-scenes content. See how your machines are born from raw metal to precision tools.

Why 1250+ customers Choose Vorlinn?

Don't Just Take Our Words for It ,Listen To Our Clients Say To Us

Latest Blog Posts

Your Questions, Answered

Vorlinn offers a warranty period of one years from the date of delivery, ensuring machine quality and functionality during this time.

Vorlinn provides free training on machine operation and technology-related queries during the warranty period. They ensure that customers are well-equipped to handle the machinery effectively.

Customers are invited to inspect the machines at Vorlinn’s factory or send a third party for verification. Additionally, Vorlinn’s technicians can visit the customer’s factory for installation and final adjustments, ensuring optimal performance from the start.

If a direct visit is not possible, Vorlinn provides detailed user manuals and instructional videos to guide customers through the installation and operation processes, ensuring they can manage setup and start production without a direct technician visit.

Vorlinn advises regular checks for adequate lubrication, ensuring clean equipment, securing all connectors or fasteners, and routinely verifying the operation of switches and handles to maintain optimal machine performance.

Vorlinn emphasizes the importance of strict adherence to safety protocols, including proper training, the use of safety signs where electricity is present, and ensuring that all operators are well-versed in emergency procedures to prevent accidents.

Vorlinn customizes machines based on specific customer requirements and current market trends, involving experienced designers from various regions to ensure innovative and effective roll forming solutions.

After receiving the down payment, Vorlinn typically prepares the machine for delivery within 40-45 days, ensuring that all specifications and quality checks are met before shipping.

Vorlinn’s roll forming machines are capable of processing various types of materials, including aluzinc, galvanized steel, and colored steel coils, providing versatility in production capabilities.

Vorlinn includes essential spare parts like bearings, buttons, chains, magnetic valves, and protective tubes with their roll forming machines to help with maintenance and repairs.